2022 China New Design Zipper Bag Stand Up Pouch Sealing Machine - Vertical Form Fill & Seal Machine – Yilong Detail:

Product Specifications

| Parameters | 300P | 300G | 300L |

| Material | Body: SS304 (Stainless Steel) SS316 Option | Body: SS304 (Stainless Steel)SS316 Option | Body: SS304 (Stainless Steel), SS316 Option |

| MeasuringTechnology | Auger Filler for Powder Packing | Volumetric Cup Filler for Granular Item Packing | Piston Pump Filler for Liquid Packing |

| ControllerTechnology | Programmable Logic Controller (PLC) & HMI Touch Screen | Programmable Logic Controller (PLC) & HMI Touch Screen | Programmable Logic Controller (PLC) & HMI Touch Screen |

| Bag Type | Back Sealed Stickpack, ThreeSide-Seal or Four-Side-Seal Bag Options | Back Sealed Stickpack, ThreeSide-Seal or Four-Side-Seal BagOptions | Back Sealed Stickpack, ThreeSide-Seal or Four-Side-Seal BagOptions |

| Filling Range | 0~50 mL | 0~50 mL | 0~50 mL |

| Bag Length | 50~230 mm | 50~230 mm | 50~230 mm |

| Bag Width | 30~120 mm (One size within this range to be fixed) | 30~120 mm (One size within this range to be fixed) | 30~120 mm (One size within this range to be fixed) |

| Packaging Film | Laminated Film, OPP/CPP,OPP/CE, PET/PE, NILO/PE, PE | Laminated Film, OPP/CPP,OPP/CE, PET/PE, NILO/PE, PE | Laminated Film, OPP/CPP,OPP/CE, PET/PE, NILO/PE, PE |

| Packing Speed | 30 – 40 bags/min | 30 – 40 bags/min | 30 – 40 bags/min |

| Filling Accuracy | ±1 ~2% Depending on Packet Size | ±1 ~2% Depending on Packet Size | ±1 ~2% Depending on Packet Size |

| Power & Supply Voltage | 1.5 kW, 220V,50/60Hz | 1.5 kW, 220V,50/60Hz | 1.5 kW, 220V,50/60Hz |

| Crate Dimensions(LxWxH) | 1100mmx 1000mm x 2000mm | 1100mmx 1000mm x 2000mm | 1100mmx 1000mm x 2000mm |

| Gross Weight | 300kg | 300kg | 300kg |

| Net Weight | 250kg | 250kg | 250kg |

bag type

This single-lane granular and free-flowing powder packing stickpack machine can be customized to produce back-sealed stickpacks, shaped stickpacks, and 3-side and 4-side sealed sachets.

Fintelligent

Filler Options

Auger Filler (for powder products)

Volumetric Cup Filler (for grains)

Tablet Counting Filler (for tablets)

Piston Pump Filler (for liquid products)

Standards

In accordance with CE Standards

Optional Equipment

Screw elevator/conveyor for automatic continuous feeding of powder products

Z-bucket elevator for automatic continuous feeding of granular products

Agitator/mixer for liquid or paste products

Product counter and stacking belt conveyor

Extra filler equipment for different powder, granular, liquid, or part type products packaging in a single machine. The choices are: volumetric cup filler, multi-head weigher, piston pump filler, auger filler, tablet counting filler, and vibrating filler

Product Specifications

| Number |

name |

quantity |

| 1 | Tool box |

1 |

| 2 | Allen key |

1set |

| 3 | Open spanner |

1set |

| 4 | Iron brush |

1 |

| 5 | Philips screwdriver |

1 |

| 6 | slotted screwdriver |

1 |

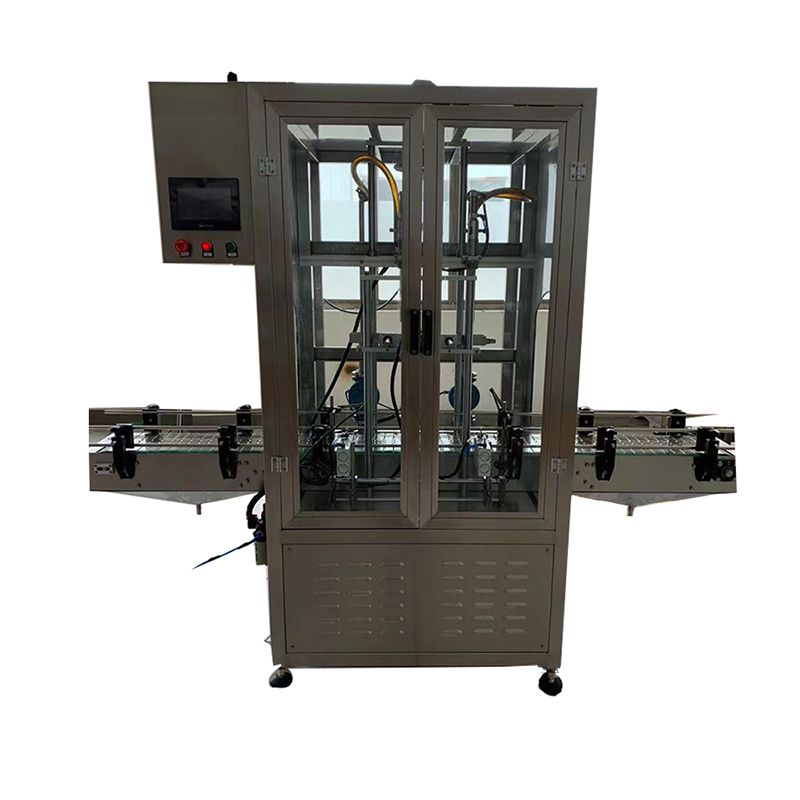

Product detail pictures:

Related Product Guide:

Being supported by an advanced and specialist IT team, we could give technical support on pre-sales & after-sales services for 2022 China New Design Zipper Bag Stand Up Pouch Sealing Machine - Vertical Form Fill & Seal Machine – Yilong , The product will supply to all over the world, such as: Auckland, Borussia Dortmund, belarus, Based on products with high quality, competitive price, and our full range service, we have accumulated professional strength and experience, and we have built up a very good reputation in the field. Along with the continuous development, we commit ourselves not only to the Chinese domestic business but also the international market. May you moved by our high quality products and passionate service. Let's open a new chapter of mutual benefit and double win.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.